When doing bikepacking races and ultra-distance cycling, gears should be available that are comfortable to pedal in all situations, including climbing when heavily fatigued. Gears should be low enough so the riders won’t fatigue unnecessarily quickly or injure themselves due to using an excessively low cadence. This page covers how to determine what lowest gear might be needed, what range of gears is appropriate and what options exist to achieve these goals.

Page Contents:

Low Gear Ratios

To calculate the size of the lowest gear you need, you should begin by determining what speed you can maintain on a certain climb and what pedaling cadence is tolerable.

Sustainable Climbing Speed

First, you need to either know the rate of climbing you can sustain, known as VAM and measured in vertical meters per hour (e.g., 800 m/h, as shown on many bike computers or activity tracking websites) or your sustainable power in watts (e.g., 200 watts, measured using a power meter or estimated on activity tracking websites). Second, what are the average gradients for the steepest long climbs on the route that you’re preparing for? For instance, two of the climbs on the 2016 Transcontinental Race (TCR) route had sustained sections of 10% gradient at elevations above 1500 meters.

VAM (in vertical meters per hour) can be turned into cycling speed (km/h) at a certain gradient (in %) using this formula:

Speed = VAM / (10 * gradient)

Using the numbers from the 2016 TCR route gives: 800 / (10 * 10) = 8 km/h.

Sustainable power can be turned into speed at a certain gradient using this calculator. Taking the same values as in the What Determines Cycling Speed? section (weight = 85 kg for rider+bike+equipment, CdA = 0.43, Crr = 0.004 and drivetrain losses = 5%) then a power of 200 watts on a 10% gradient equates to a speed of 7.8 km/h.

At an elevation of 1500 meters, a cyclist’s available power is generally reduced by about 10% compared to sea level due to the reduced oxygen (see the Environmental Effects on Cycling Speed: Wind, Elevation & Air Temperature page). The revised estimates for these specific Alpine climbs are therefore 720 m/h and 180 watts, which translate to 7.2 or 7.0 km/h.

Minimum Cadence

Research shows that what cadence a cyclist prefers to use doesn’t have a massive or consistent effect on their power or fatigue as long as it is within a reasonably broad range. However, most experts agree that using a cadence lower than about 60 rpm for an extended period puts extra strain on the muscles, thereby causing unnecessary fatigue and increasing the chance of injuries developing.

Although cadence information generally isn’t very useful when riding, it’s a good idea to use a cadence sensor occasionally to be aware what different values feel like and to know what is the minimum that you can comfortably maintain, which may depend partly on your Crank Length.

How Low Should You Go?

Based on your anticipated speed and minimum tolerable cadence, are the gear ratios on your bike sufficient?

A common setup on a road bike adapted for climbing is a compact road crankset with 50-34 chainrings and an 11-32 cassette, which gives a lowest gear of 34:32 or a ratio of 1.06:1. There are useful tools for turning speed into cadence when using a certain gear ratio here and here. They show that the cadence when riding at 7 km/h with this gearing would be 52 rpm, which is worryingly low. If the rider wants to maintain a more comfortable cadence of 60 rpm on such a climb then the chainrings, cassette or both should be changed to have a lowest ratio of no more than 0.92:1.

This result of needing a 0.92:1 gear ratio only applies to this one specific example and the values that I’ve assumed. Being able to sustain 200 watts (or 800 vertical m/h) even when fatigued and having a total weight with bike and equipment of 85 kg are rough values and may be over-estimates for typical ultra-distance cyclists. In addition, I assumed a tire size of 700C x 25mm. Tire diameters from as small as 650B x 35mm up to 700C x 40mm are common but wouldn’t change the result by more than about +/-2 rpm. To keep things simpler, I only present gear ratios on this page and ignore the very minor effect of tire size, but you can include this when doing your own calculations.

Having an even lower gear ratio than 0.92:1 may therefore be advisable for many people. Personally, I prefer to have a lowest gear ratio of around 0.83:1 when doing ultra-distance rides and I also appreciate having that gear available on local shorter, hilly rides.

To summarize, the lowest ratio needed for most people when doing typical self-supported, ultra-distance cycling events will be somewhere in the range from 0.8:1 to 1.0:1. Subsequent sections address the options of how to obtain such gearing, but I first need to address what total gear range is needed by assessing what are the fastest gears that are likely to be needed for this type of cycling.

High Gear Ratios

The fastest gears on most road bikes get used very rarely when doing ultra-distance rides because it’s better to conserve energy and not pedal when the speed goes above about 45 km/h rather than wasting energy fighting the wind for a relatively small increase in speed (see the Riding Technique & Efficiency page). Even if you tend to pedal at much faster speeds when training, after a couple of long days on the bike, it is likely that you’ll switch into a pure energy-conservation mode and rarely pedal on significant downhills.

At a cadence of 90 rpm (which is very comfortable and most people can handle significantly more), a 50-tooth chainring and a 12-tooth cog gives a speed of 47 km/h. That’s a gear ratio of 4.17:1, so a highest gear ratio of around 4:1 should be sufficient for ultra-distance cycling.

James Hayden, the winner of the 2017 TCR, came to the same conclusion and chose to put a highest gear of 46-12 on the bike that he ended up winning the race with, a ratio of 3.83:1. He also said his lowest gear of 34-32 (1.06:1) wasn’t quite low enough on certain climbs during the race, even for him.

Gear Range and Steps Between Gears

To summarize the above advice, a range of gear ratios from about 0.8:1 to 1.0:1 up to about 3.8:1 to 4.0:1 is reasonable. Total desired gear range in percentage is therefore 380 to 500% (4.0/0.8 * 100% = 500%), so I’ll use 400% to keep things simple.

To decide what cassette and crank options are best to achieve this range, you must also consider the gaps between gears that you can tolerate based on the cadence range that you’re comfortable pedaling with.

The relative difference between two gears can be determined by dividing the size of the larger cog by the next smallest, and this equates to the difference in cadence between those gears. For example, moving from a 15-tooth to a 17-tooth cog is a 13.3% decrease in gearing (17/15 = 1.1333) or a 13.3% increase in pedaling cadence, which most people have no problem with. Some cassettes have a jump between a 19-tooth cog and a 22-tooth cog, which is a 15.7% difference that I find to always be noticeable and uncomfortable. Note that these calculations could be reversed (15/17 instead of 17/15) so that the values would alter, but the conclusions wouldn’t change.

To keep my pedaling cadence and power reasonably constant, I try to minimize the number of gaps between gears that are more than 15%. Other people may not be overly bothered by gaps of up to 20%. Differences in tolerance to these gaps is an important individual difference and explains why different people end up with rather different gearing setups to achieve similar goals.

Cranksets & Chainrings

One or Two Chainrings?

The most important consideration when choosing the chainring and cassette combination to achieve your desired gearing characteristics is whether having only one chainring can give sufficient range for you while still having reasonable spacing between gears.

On mountain bikes, having only one chainring has significant advantages because it gives better chain retention on rough terrain, rear suspension works better if the chainring size doesn’t change and it eliminates the need to make clunky shifts between chainrings under power. Having only one chainring causes there to be larger gaps between the cog sizes, but that can be a bonus rather than a hindrance when mountain biking because changes in gradient often occur quicker on trails than on roads, so having larger gaps means that fewer double shifts are needed to make large gear changes. I therefore understand the appeal for single chainring setups when mountain biking.

More and more gravel bikes and some road bikes are now equipped with only one chainring. I have strong reservations about whether that is a good idea due to having to compromise either gear range or spacing compared to what can be achieved with two chainrings.

If a gear range of at least 400% is desired (e.g., from 4:1 to 1:1) then with 12 cogs you could ideally have 11 even steps of 13.4% between gears, but even if a cassette with such a range existed (which is currently doesn’t, see the Cassettes section below) then the steps would not be constant because tooth counts have to be whole/integer numbers (e.g., a cog with 11.34 teeth is impossible) and so several of the gaps would be 15-20%, which is not ideal for road riding for most people. 11-speed gearing is far more common, and with that the steps would need to average 14.9%, meaning that many of the gaps would be larger than what many people find is ideal for road riding.

By using two chainrings, the gear range can be well over 400% while still having reasonable spacing between all gears. The extra weight for the chainring, front derailleur and shifter is very marginal at around 200 grams. Such a weight difference won’t have a significant effect on overall riding speed (see The Actual Effect of Weight on Cycling Speed page), so it shouldn’t be a factor when considering which gear setup is better for you. Front derailleurs aren’t too difficult to adjust and they hold their adjustment well, so I don’t see any disadvantage to having a front derailleur on a road or adventure/touring bike. Some people see an aesthetic or fashion advantage to having only one chainring and no front derailleur, but those aspects have zero influence on my gearing decisions.

An additional disadvantage of using only one chainring is that drivetrain friction is slightly increased while using faster gears because chains are less efficient when going around tighter circles under load. For instance, a person using a single 40-tooth chainring and a cog with 10 teeth to have a 4:1 ratio will lose an additional 1-2% of their energy to drivetrain inefficiencies compared to someone with a 48-tooth large chainring using a 12-tooth cog to obtain the same ratio. The efficiency difference is not huge, but it is far larger than the very marginal effect that the small difference in weight between the two setups has.

In conclusion, the advantages of single chainrings are far less important when cycling mostly on paved roads than when mountain biking on trails. In my opinion and experience, it’s not possible to have a decent range of gears and at the same time have reasonable spacing between most gears with only one chainring. Therefore, I strongly recommend using two chainrings when riding mostly on paved roads, which is the type of riding that this site is focused on.

Adventure / Gravel Double Cranksets

The conclusion from the example above with someone who can sustain 200 watts / 800 vertical meters per hour at sea level and is planning to ride up some sustained 10% gradients at over 1500 m elevation and has a total weight of rider, bike and gear of 85 kg is that they would need a gear ratio of no more than 0.92:1 to maintain a cadence of at least 60 rpm in that situation. If they cannot sustain that power when fatigued, they have a higher total weight, or they want to maintain a higher cadence than 60 rpm then they’ll need even lower gearing, which is why I prefer a lowest ratio of about 0.83:1 on my personal bike.

Regular compact road cranksets have 34-50 chainrings and the biggest 11-speed Shimano road cassette is 11-34, which gives a lowest ratio of 1:1, which would be insufficient in this situation. To reduce the gearing, either the small chainring needs to be smaller or the largest cog needs to be larger. As explained in the Cassettes section below, using a larger cassette may not be ideal because it would have larger spacing between the gears and may not be compatible with the rear derailleur. A better option may therefore be to use a what is occasionally called a “super-compact” crankset, but is more often referred to as a gravel or adventure crankset.

Many brands now offer gravel/adventure cranksets with 30-46 chainrings or 32-48, including Shimano in their GRX range and FSA in their Adventure range. Shimano chainrings tend to give the best shifting performance and durability and bottom brackets are available for every type of frame that fit the 24mm Shimano axle, so I generally recommend Shimano cranks and I don’t see the need to list all other options here.

Using a 30-46 crank with an 11-34 cassette gives a reasonably low gear of 0.88:1, a top gear of 4.18:1 and that’s a range of 474%. The top gear may be larger than needed and the spacing of that cassette is not ideal, so other options are listed in the Cassettes section below.

With a crank that has 46 or 48 teeth, the teeth are not as high as on a normal road crank, so it can be a problem to move the front derailleur low enough for crisp and reliable shifting. Fortunately, the Shimano GRX component groups include front derailleurs that are designed for this and also for the chainrings to be slightly further from the frame. A guide or chain catcher may also be useful to prevent derailments when using extra-wide chainring differences. The most robust chain guide is the K Edge Cross Double XL (braze-on mount: Amazon or clamp-on mount: Amazon) and there is also the SRAM Chain Spotter (Amazon).

Mountain bike double cranksets offer even lower gearing options (e.g., 26/38 or 28/42). However, MTB cranks have longer axles than road cranks to give more clearance due to accommodating wider MTB tires and rear axles. Such cranks therefore have the pedals and chainrings wider apart than on a road or gravel crankset. Some people find that riding with their feet wider apart is less comfortable and again the wider chainline and smaller chainrings often don’t work well with road front derailleurs.

Other options for having a crank with chainrings smaller than 30-46 but without using a MTB crank with a long axle is to use a road triple crank and only use the inner two chainring positions or to use a White Industries VBC crank, which now has a 30mm axle version as well as the square taper axle. Spécialités TA have alumnimum and

Cassettes

The two tables below include 11-speed and 12-speed cassettes that meet certain criteria and were available in late 2019.

Firstly, because large chainrings can be 55% bigger than small chainrings (e.g., on a 46-30 crankset), a cassette with a gear range of at least 260% can be sufficient to obtain a complete gear range of 400% when two chainrings are used. Therefore, 260% is chosen as the minimum gear range to be included in the table.

How tolerant different people are to gaps between gears was discussed in the Steps Between Gears section above, with the conclusion being that gaps that exceed 15% between adjacent gears are quite noticeable and it’s best when these are minimized. Therefore, the number of such gaps and the size of the largest gap are important characteristics of a cassette and when cassettes with a certain gear range is available from multiple brands, only the version that has better spacing in terms of the fewest gaps of more than 15% is included.

Brands considered were Campagnolo, IRD, KCNC, Miche, Shimano, SRAM, and SunRace. In my experience, shifting between cogs is smoothest on Shimano cassettes, slightly inferior with SRAM and Campagnolo, and generally poorer on cassettes from other brands, which is why I’ve ignored other brands when there is a decent option from one of the 3 main brands.

Cassettes with 9-tooth cogs were not considered because they are too inefficient and not durable (which is why there are not offered by any of the 3 main brands). Hope and Rotor cassettes were not considered because they do not fit on wheels from other brands.

The largest cog size that a rear derailleur can handle is an important consideration when choosing a cassette, so that is covered in the next section.

There are often multiple versions of the same cassette offered by a manufacturer at different price levels. This is ignored here because generally the cog sizes and shifting ramps are identical across all versions, so shifting should be very similar. The differences are whether the larger cogs are mounted to lightweight carriers or are heavier individual cogs, the finishing of the material, and sometimes the material of the cogs and/or lockring.

Which type of freehub body is needed for each cassette is noted and this is possible to change on many wheels. A lot of cassettes work on Shimano/SRAM 11-speed freehub bodies (denoted Sh/SR-11). Shimano 11-speed cassettes with at least 34 teeth fit on the slightly narrower 8/9/10-speed Shimano freehub body (found on older wheels and MTB wheels) and can also be used on 11-speed freehubs by using a spacer, and so are denoted Sh/SR-10+11. ‘Shimano MS’ refers to Shimano’s ‘MicroSpline’ 12-speed MTB freehub body, which is currently only available for certain wheels. Campagnolo bodies have been the same for everything from 9- to 12-speed road cassettes. SRAM cassettes with a 10-tooth cog require the SRAM XD body for MTB cassetttes and the XDR version for 12-speed road cassettes (which is slightly longer).

Please use the Contact Form to inform me of any missing or incorrect information.

11-Speed Cassettes

Spacing between cogs is the same for all 11-speed systems, so all cassettes should work with 11-speed systems from other brands.

| Tooth Range | % Range | Brand | Freehub Body | Steps > 15% | Largest Step |

|---|---|---|---|---|---|

| 13-34 | 262% | Miche | Sh/SR-11 | 0 | 13.3% |

| 11-29 | 264% | Campagnolo | Campagnolo | 0 | 13.3% |

| 12-32 | 267% | IRD / Miche | Sh/SR-11 | 0 | 14.3% |

| 11-30 | 273% | Shimano | Sh/SR-11 | 0 | 14.3% |

| 12-34 | 283% | Miche | Sh/SR-11 | 0 | 14.3% |

| 11-32 | 291% | Shimano | Sh/SR-11 | 0 | 14.3% |

| 12-36 | 300% | IRD | Sh/SR-11 | 1 | 15.4% |

| 11-34 | 309% | Shimano | Sh/SR-10+11 | 2 | 18.2% |

| 11-36 | 327% | SRAM | Sh/SR-11 | 2 | 15.8% |

| 11-38 | 345% | KCNC | Sh/SR-11 | 4 | 17.6% |

| 11-40 | 354% | Shimano | Sh/SR-10+11 | 2 | 18.2% |

| 11-42 | 382% | Shimano | Sh/SR-10+11 | 4 | 18.2% |

| 10-42 | 420% | SRAM | SRAM XD | 5 | 20.0% |

| 10-46 | 460% | Ingrid | SRAM XD | 7 | 20.0% |

Note that Miche sells custom cassettes where cogs can be chosen individually, starting with an 11, 12, or 13 tooth cog and going up to 30, 32, or 34 teeth. Range and spacing can therefore be chosen more freely, but shifting is poorer because the ‘timing’ of the shift ramps on adjacent cogs cannot be optimized as is done with complete, stock cassettes. IRD cassettes are designed in a similar way, but sold only as complete cassettes.

12-Speed Cassettes

Whereas 11-speed cassettes from different manufacturers have the same spacing between cogs and so are cross-compatible, I’m not sure whether this is true for all 12-speed cassettes.

For 12-speed cassettes, it is notable that there is a void between road cassettes that have a maximum range of 330% and MTB cassettes that have a minimum range of 450%. Hopefully someone will fill this gap in the market soon.

Due to odd choices of cog sizes, the only 12-speed cassette that outperforms the equivalent 11-speed cassette in terms of spacing is the Campagnolo 11-29. This is perplexing and I again hope that new models will be released soon that address this. Shimano is expected to announce a 12-speed road groupset during 2020 that should be available by the end of the year and may include some better cassette options.

| Tooth Range | % Range | Brand | Freehub Body | Steps > 15% | Largest Step |

|---|---|---|---|---|---|

| 11-29 | 264% | Campagnolo | Campagnolo | 0 | 13.0% |

| 11-30 | 273% | KCNC | Sh/SR-10+11 | 1 | 15.4% |

| 10-28 | 280% | SRAM | SRAM XDR | 1 | 16.7% |

| 11-32 | 291% | Campagnolo | Campagnolo | 1 | 15.8% |

| 11-34 | 309% | Campagnolo | Campagnolo | 3 | 17.2% |

| 10-33 | 330% | SRAM | SRAM XDR | 2 | 17.9% |

| 10-45 | 450% | Shimano | Shimano MS | 4 | 20.0% |

| 11-50 | 455% | SRAM | Sh/SR-10+11 | 5 | 19.0% |

| 10-48 | 480% | Ingrid | SRAM XD | 5 | 20.0% |

| 10-50 | 500% | SRAM | SRAM XD | 6 | 20.0% |

| 10-51 | 510% | Shimano | Shimano MS | 7 | 20.0% |

Rear Derailleur Compatibility

I don’t list specific derailleur models with their official cassette compatibility because there are so many models, the availability changes too frequently, and the official compatibility is only a very rough guideline as to what will and won’t work. I therefore instead give general guidelines on this topic.

Rear derailleurs can often handle a cassette with a largest cog that has 2 to 4 more teeth than officially stated, and sometimes even more. For example, a modern road rear derailluer officially rated for up to a 32-tooth cog almost always works with a 34-tooth and often with a 36-tooth cassette. Occasionally, a road rear derailleur officially rated for only 34 teeth will even work with a 40-tooth cassette.

The limiting factor for how large of a cassette cog a rear derailluer can handle is not the length of the derailluer cage, which many people incorrectly assume, but it is how low the upper pulley wheel can be positioned. This is determined by the length and angle of the bike’s derailleur hanger, the chain length and the geometry of the derailleur itself, which is why there’s no universal rule as to what will and won’t work; it’s best to try the specific combination of parts that you’re interested in on your bike rather than asking what works on someone else’s bike.

When installing a larger cassette, the position of the rear derailluer’s upper pulley can be adjusted using the B-screw, the location of which varies depending on the brand and model of the derailleur. Remember that a longer chain or at least a couple of extra chain links is often needed when installing a larger cassette so that the chain is not too short when you inevitably shift into the large chainring and largest cog.

If turning the B-screw in all the way is not sufficient for the rear derailleur’s upper pulley to clear the largest cog, a longer or reversed screw might help or a derailleur hanger extension like the Wolf Tooth RoadLink could be used to mount the derailleur much lower. However, using a hanger extension tends to decrease shifting performance significantly, especially when using the smaller cogs on the cassette and a mechanical derailleur. Therefore, if you cannot get the upper pulley low enough then I first recommend trying to reduce the chainring sizes instead of increasing the cassette size or changing the rear derailleur for a different model. Using a hanger extension should only be done as a last resort.

Shimano’s GRX (gravel) rear derailleurs can be used with shift levers from other groups and are compatible with much larger cassettes than road rear derailleurs. On 12-speed SRAM AXS systems, the MTB rear derailleur can be used instead of the road version, but that cannot be used with a front derailleur.

Custom Cassettes

Most of the cassettes in the tables above have an 11-tooth smallest cog, but that is often smaller than needed to achieve a sufficiently high gear for ultra-distance cyclists who are using two chainrings (see the High Gears section above). A 12-tooth cog is normally sufficient because it gives a highest gear ratio of 3.83 even with a 46-tooth large chainring, so I’ve often customized cassettes to eliminate one or two of the larger gaps in the cassette while still having a good range of gears.

For instance, like James Hayden did when he won the 2017 TCR, I’ve taken an 11-32, 11-speed Shimano cassette and replaced the first four cogs (11-12-13-14) with the first four cogs from a 12-25, 11-speed cassette (12-13-14-15) to obtain a custom 12-32 cassette with only the final jump between gears being 14% and all other steps being less.

After some experimentation, I’ve also made a custom 12-36, 11-speed cassette with parts from 3 different cassettes (Shimano 12-25, Shimano 11-32 and SRAM 11-36) that shifts without problems with a Di2 rear derailleur and all gaps smaller than 15% and a wide range of 300%. This is what I’m currently using on my ultra-distance bike paired with a 30-46 crankset.

Shifting across cogs that come from different cassettes, like the 15 and 16 tooth cogs in the 12-32 custom cassette example, is often a problem because the shifting ramps and gates may not be aligned. This can make shifting sluggish or the gear may only be accessible by shifting past it and then coming back. You need to try it to find out how much of a problem this will be with any specific combination. By changing which cogs come from which original cassette, you can alter where the jump between the cassettes occurs and find which combination yields the best shifting. These problems are less of an issue with electronic rear derailleurs than mechanical models because of the extra power and precision of the electronic derailleurs.

When customizing cassettes, you also need to pay attention to the position where some cogs need to be mounted. Normally, the smallest, second-smallest and the largest cogs have special shapes and need to be kept in those positions.

As mentioned above, Miche and IRD sell 11-speed, wide-range cassettes that have a 12-tooth smallest cog. However, in my experience the shift quality and durability of those cogs is not as good as it is with models from bigger brands. I’ve therefore had better success by mixing parts from stock cassettes to find combinations that work well.

Internal / Hub Gears

In addition to derailleur gears, internal hub gears are also an option. In the early days of geared bicycles, hub gears were very common in certain markets, especially the UK, but have since been completely replaced by derailleur systems for racing. They are still found on some touring bikes, city bikes, and occasionally mountain bikes.

The best internal gear systems that can be mounted on most bikes are the 14-speed Rohloff hub, which offers an excellent range of 526% with equal 13.6% spacing between each gear, and the Shimano Alfine 11-speed hub, which has a range of 409%, but has one gap of 29% in addition to 9 gaps of 13-14%. Pinion offers a bottom-bracket mounted gearbox that requires a special frame but has a version with 18 gears evenly-spaced at 11.5% intervals across a massive 636% range. Although originally designed for flat handlebars, shift levers do exist for drop handlebars.

The big advantage of these systems is that they cannot easily get damaged like derailleurs. However, they add a significant amount of mechanical resistance, estimated as at least 2%, possibly more, and are slightly heavier than equivalent derailleur systems. This translates into at least a 1.5% difference in speed for a given amount of power, which can add up to a lot over a very long race, see the Mechanical Resistance page. In addition, these systems tend not to shift as well under pedaling load as derailleur systems.

In summary, not many ultra-distance cyclists use such systems, but they could offer some advantages due to the gear range, spacing and durability.

Summary

Hopefully this page has given you an idea of how to choose appropriate gearing and the options that are available. There is also a good article at road.cc about methods to get lower than regular gearing on a road or gravel bike, but that was written before many of the newer gravel bike options were released.

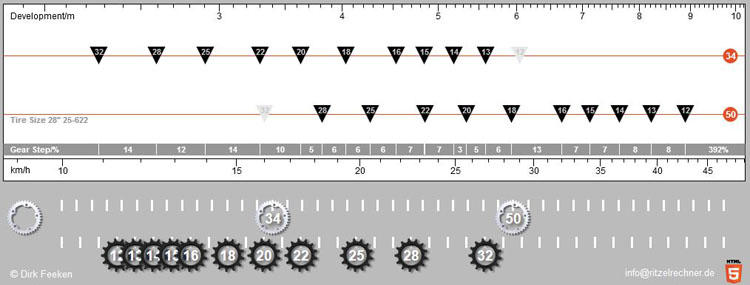

A useful tool for visualizing different gear setup is this online gear calculator, an example output of which is below.

Last significant page update: November, 2019

This is the final page in the Bike & Bike Components section, which is in Ride Far, Part II: The Bike.